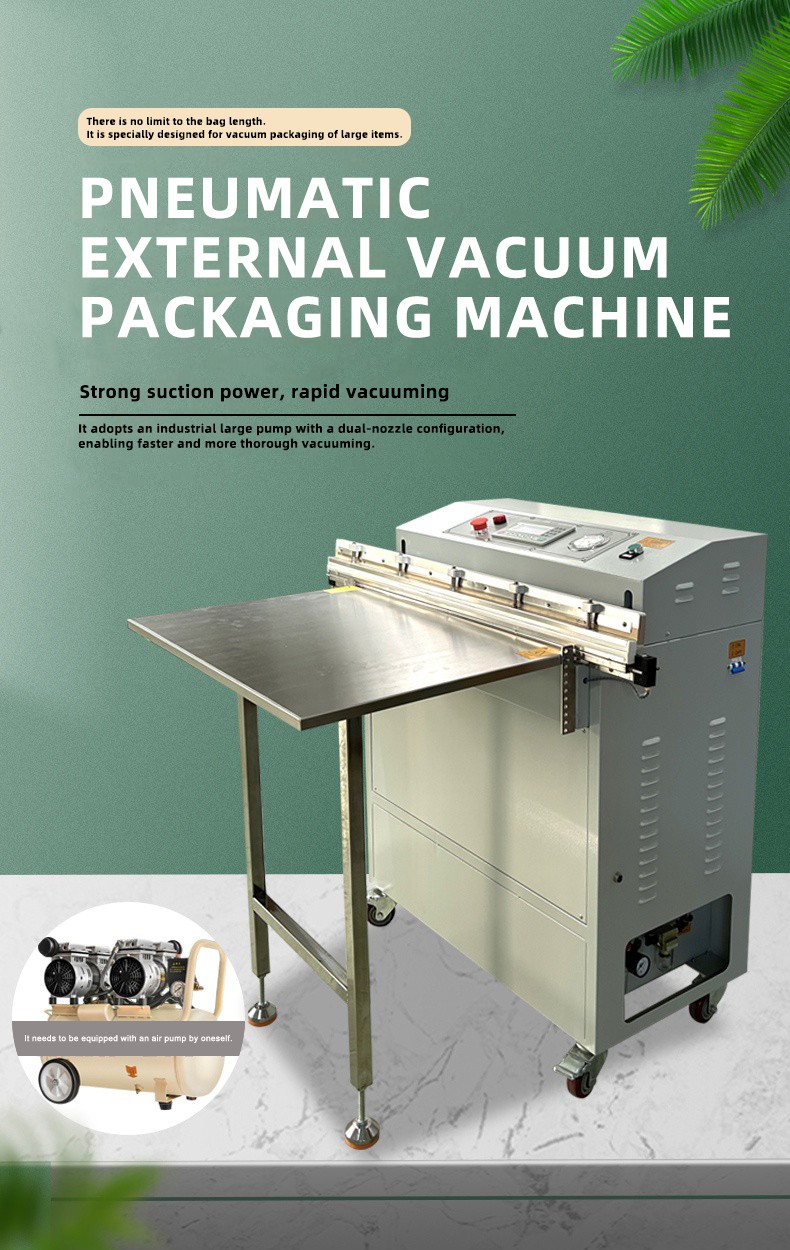

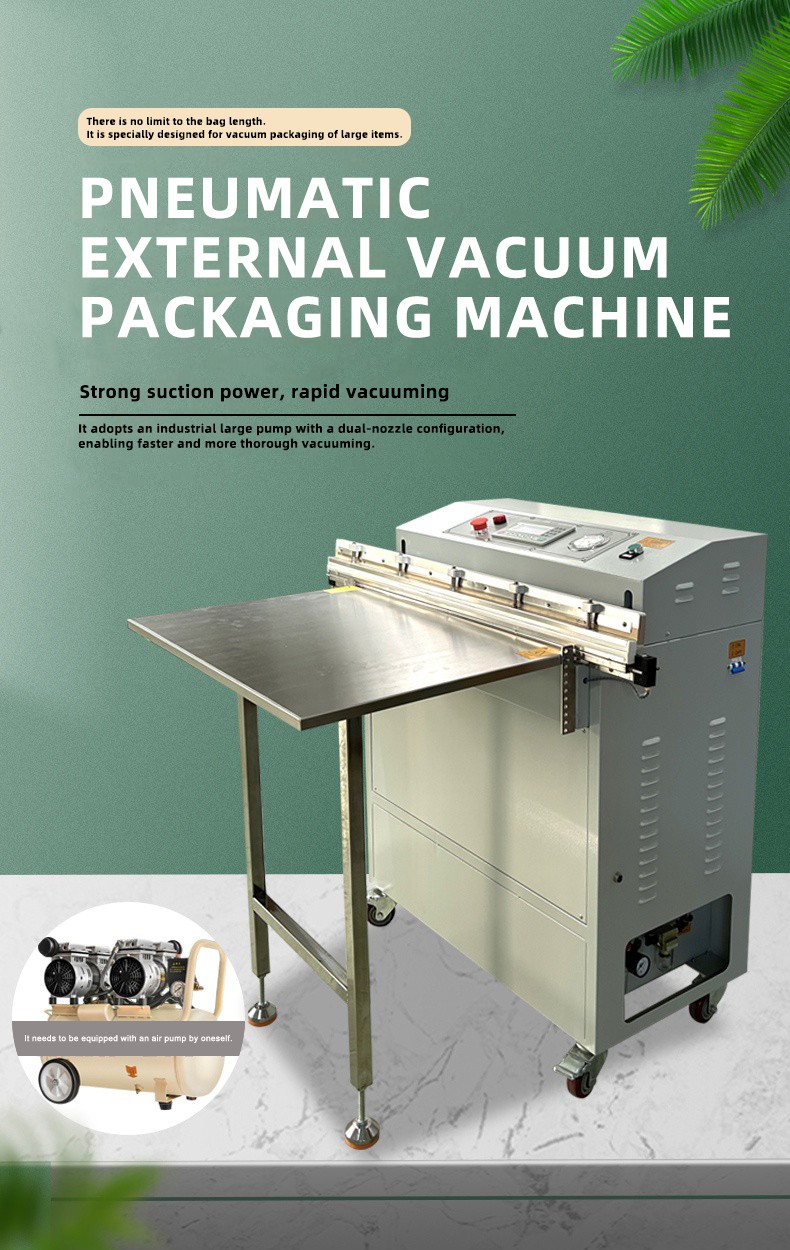

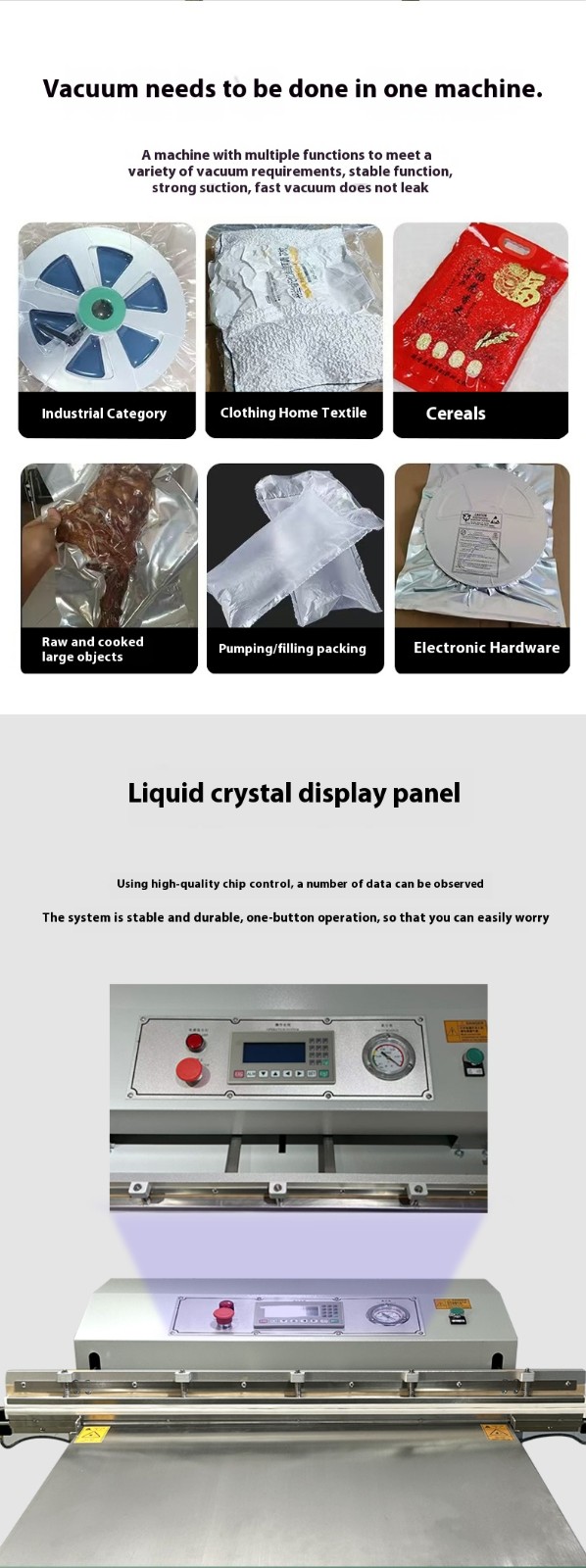

The vertical external vacuum packaging machine integrates multiple functions, enabling vacuum sealing to preserve freshness without air leakage.

With its unique structural design and functional features, the external vacuum packaging machine demonstrates significant advantages in packaging efficiency, application range, operational flexibility, and more. It is particularly well-suited to meet the diverse packaging needs across multiple industries, with specific advantages detailed in the following five core dimensions:

Unlike internal vacuum packaging machines that rely on a vacuum chamber, the external vacuum packaging machine achieves vacuum extraction through an external suction nozzle, completely breaking free from the limitation that "packaging size is determined by the size of the vacuum chamber." For irregularly shaped products (such as angular handicrafts, hardware accessories assembled from multiple components, and fresh meats of various shapes), smooth packaging can be achieved simply by adjusting the position of the suction nozzle and the height of the workbench.

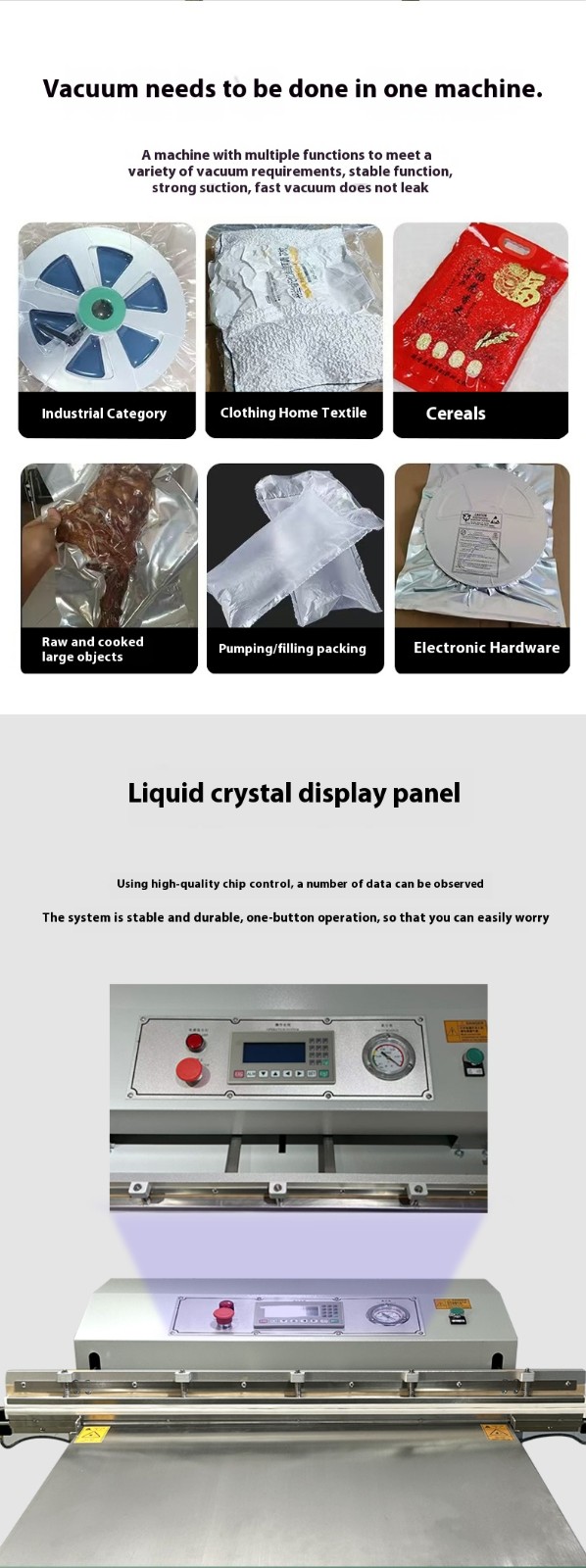

The external vacuum packaging machine has extremely low requirements for the material, size, and thickness of packaging bags. It does not require specially customized bags, and any ordinary sealable packaging bag can be used: whether it is a regular composite bag (PE/PA composite bag, aluminum foil composite bag) or a single-material bag (PE bag, PP bag), it can work normally as long as the bag mouth can fit the suction nozzle and meet the heat-sealing conditions. For example, ordinary transparent composite bags commonly used in the food industry, anti-static shielding bags in the electronics industry, and thickened woven bags in the hardware industry can all be directly used without replacing the equipment or adjusting complex parameters. Compared with internal vacuum packaging machines that "require customized bags matching the size of the vacuum chamber," this greatly reduces the procurement cost of packaging materials and inventory pressure.

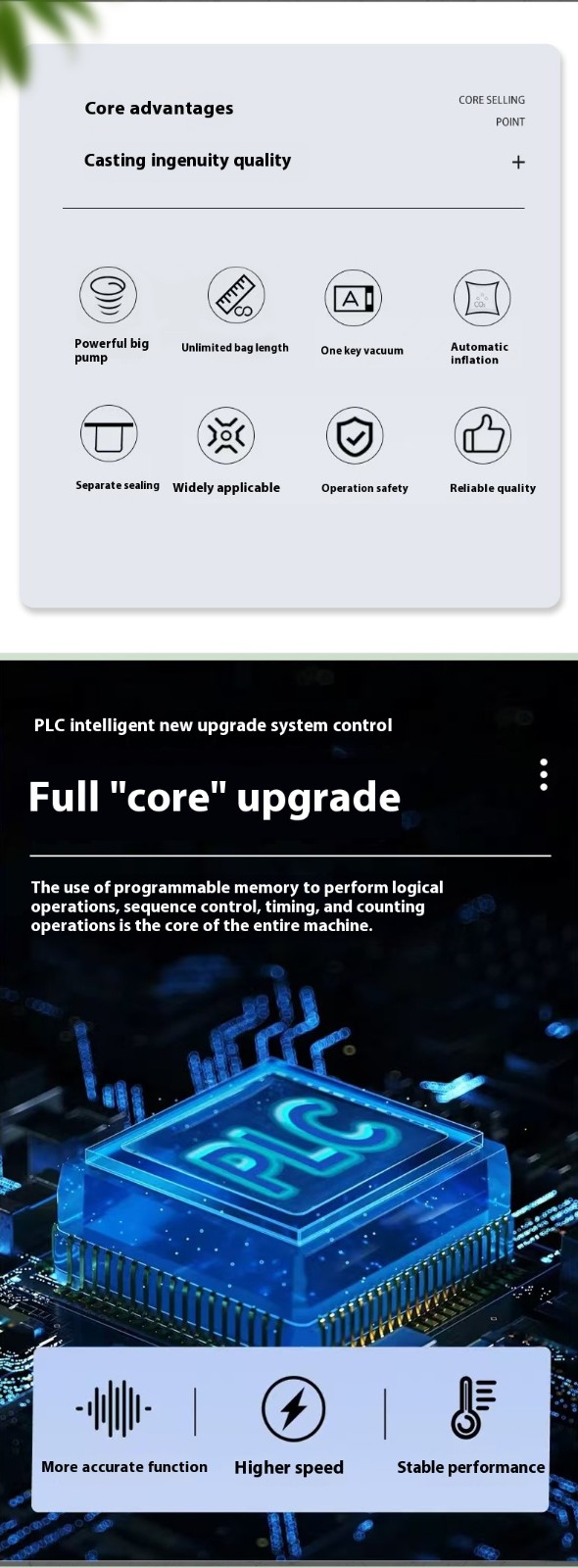

The external vacuum packaging machine supports quick switching between multiple working modes, enabling flexible adaptation to the packaging needs of different products:

- The basic mode can realize integrated "vacuum extraction + sealing" operation, meeting the vacuum preservation/protection needs of most products;

- For fragile products (such as biscuits, pastries, and glassware), the "vacuum extraction + gas filling" mode can be activated (first extracting air, then filling with inert gases such as nitrogen and carbon dioxide), which not only isolates oxygen to extend the shelf life but also uses gas cushioning to protect products from extrusion;

- For scenarios that only require sealing without vacuum extraction (such as packaging small bags that have already undergone vacuum treatment), the independent "sealing" function can be activated to avoid waste of equipment functions.

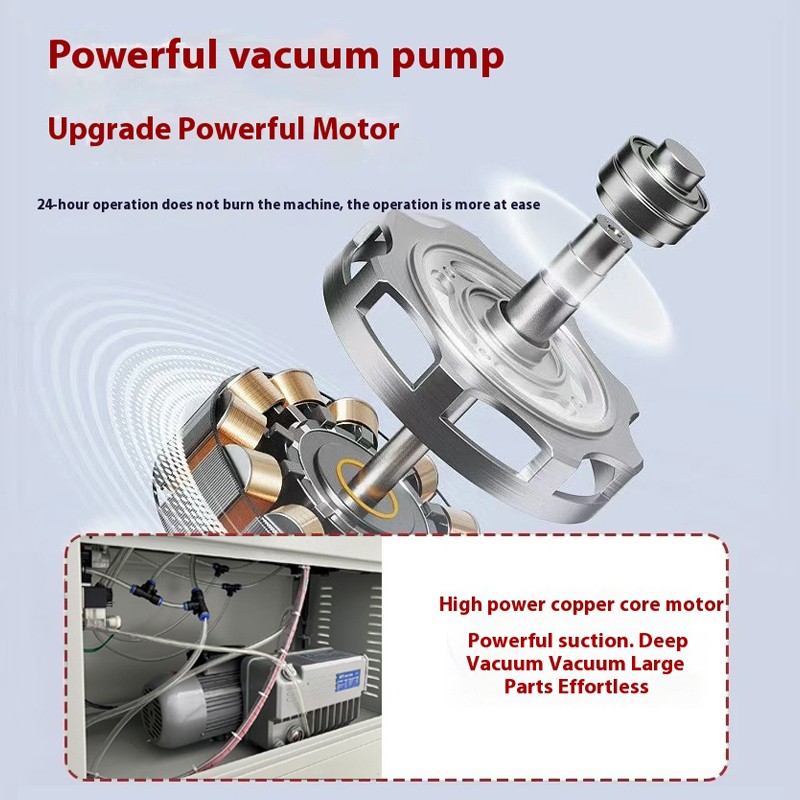

In addition, some models are equipped with dual suction nozzles or movable workbenches. During batch packaging, a streamlined operation of "placing the bag - vacuum extraction - sealing - taking the bag" can be realized, and the overall efficiency is more than 30% higher than that of manual internal vacuum models.

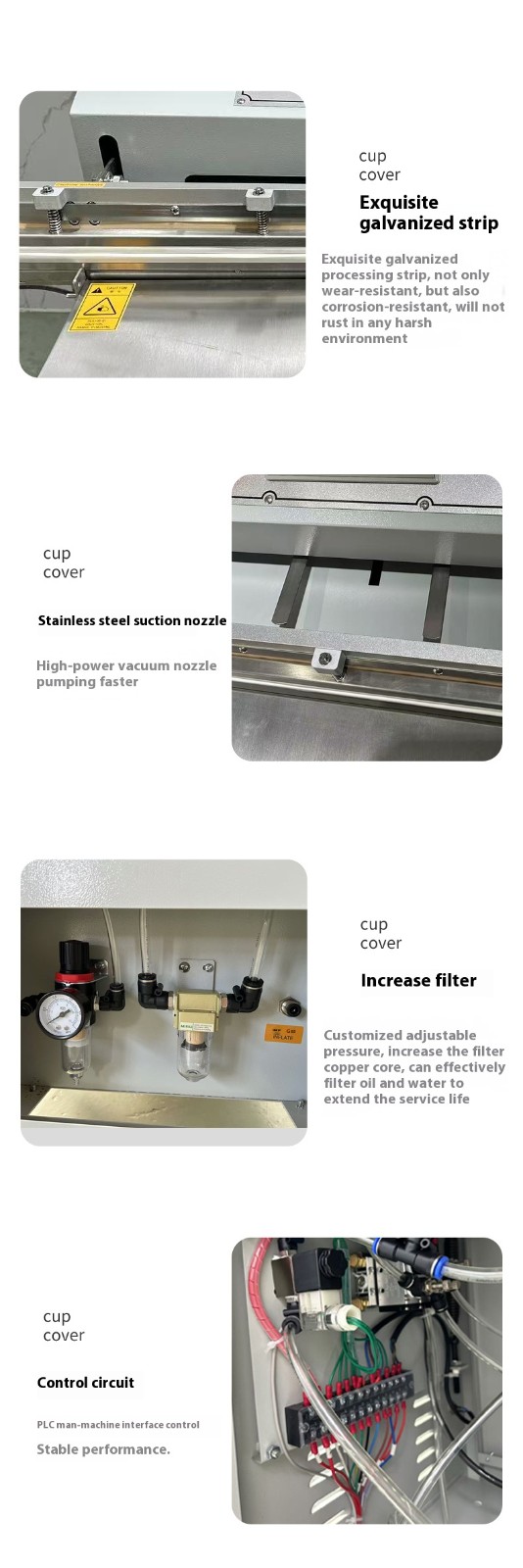

The equipment is equipped with a precision vacuum sensor and an adjustable vacuum system, allowing precise setting of the vacuum degree (common range: 1-20 mbar) according to product characteristics:

- When packaging high-demand foods (such as cooked meats, seafood, and freeze-dried foods), the vacuum degree can be adjusted to ≤5 mbar to completely extract air from the bag, inhibit the growth of aerobic microorganisms, and extend the shelf life by 2-5 times;

- When packaging pressure-sensitive products (such as fluffy bread and soft textiles), the vacuum degree can be appropriately reduced (10-15 mbar) to avoid product deformation caused by excessive vacuum extraction;

- When packaging electronic components and hardware parts, a high vacuum degree (≤2 mbar) can be set to prevent moisture and oxygen from entering, which would otherwise cause oxidation of components and rusting of parts.

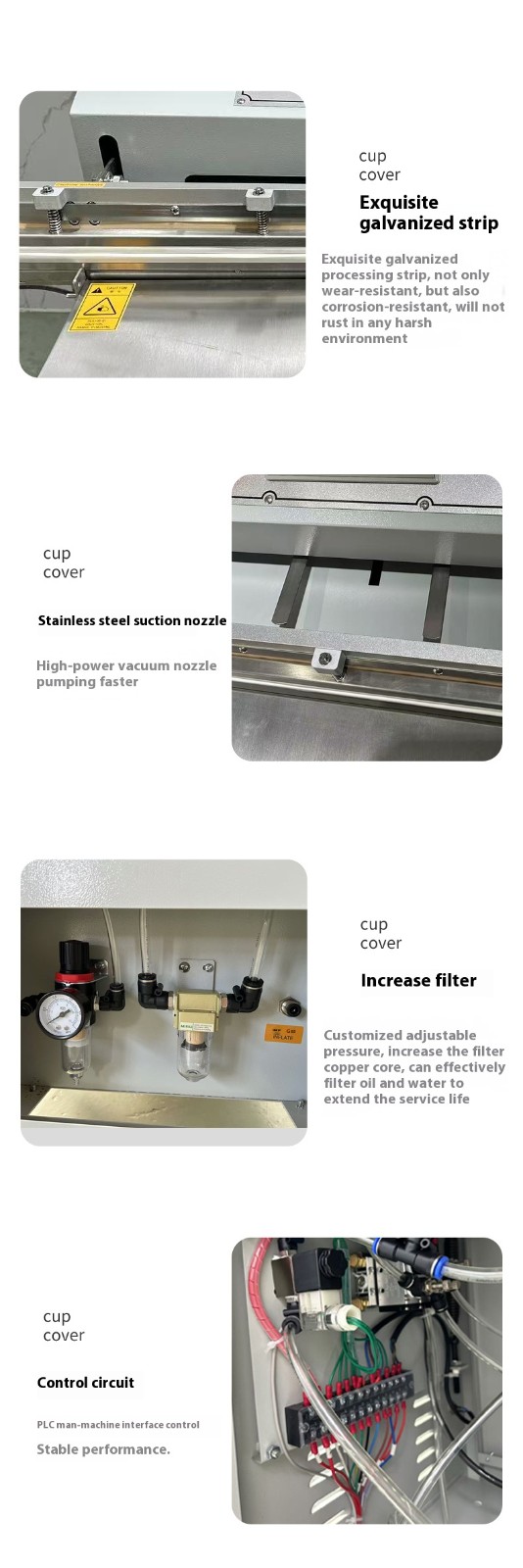

At the same time, the heat-sealing system of the equipment adopts constant temperature control and wide sealing strips (common width: 8-15 mm). The sealing temperature (160-220°C) and time (1-5 seconds) can be adjusted according to the thickness of the packaging bag, ensuring flat and firm sealing. Tests show that there are no air bubbles when the sealed packaging bag is immersed in water, and tools are required to tear open the seal, effectively avoiding the problem of "air leakage and failure" during transportation.